NOVA

About us

FROM DESIGN TO PRODUCTION

NOVA company is a manufacturer of electronic equipment used by data centers. The company’s offices and production facilities are located in Almaty, Kazakhstan. The company has its own qualified engineering staff interacting with the designers and engineers of the customers. The company’s modern production equipment allows for both manual installation and automatic installation of electronic components on boards. We select an individual solution for each task and we interact with the client at all stages of the work performed.

OUR PRODUCT LINE

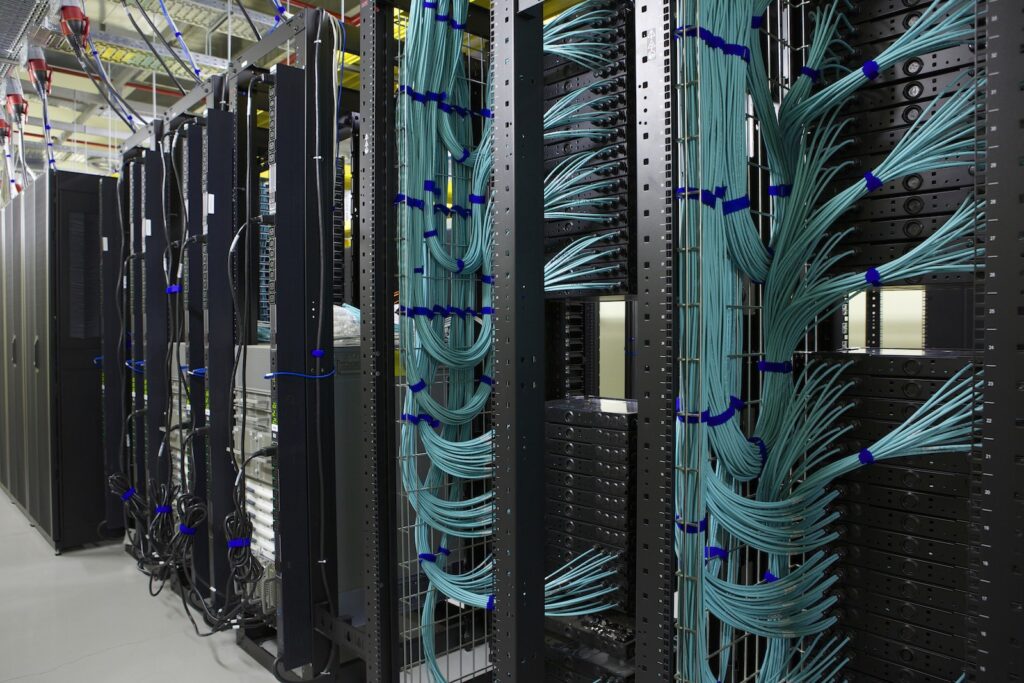

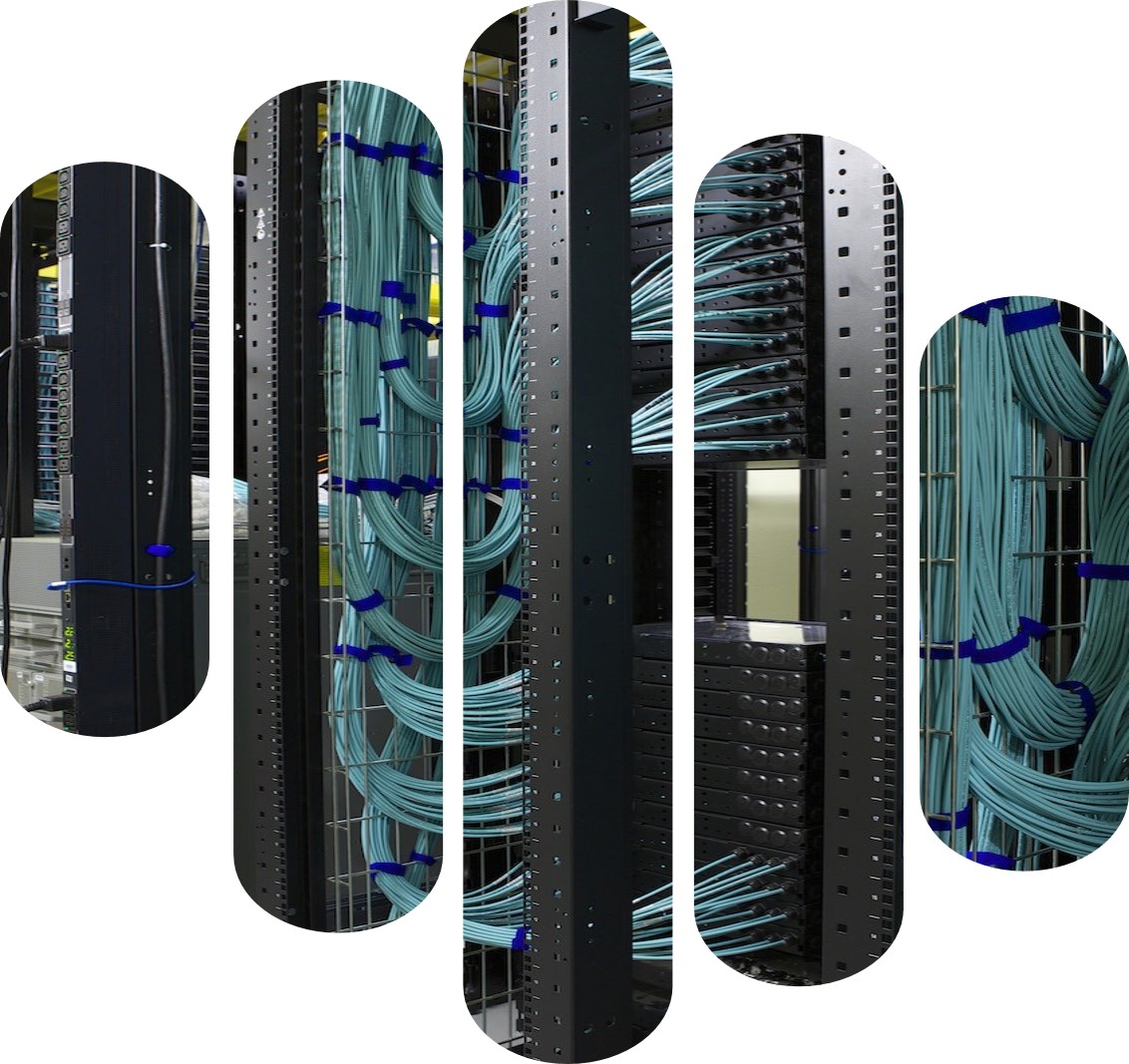

As confidence has increased in Cloud-based operations, many organizations in the private and public sectors are outsourcing some of their services and facilities. Critical infrastructure equipment suppliers are responding to the challenges of a shifting IT paradigm by innovating throughout their product ranges. Most rack, power and cooling systems manufacturers will offer small to medium to large scale solutions which tend to feature some common architecture, firmware and software and features. Newer developments that are also migrating into the server room facility include hot and cold aisle containment and self-contained micro data centres. With our partner we successfully run wide set of server room and server equipment

THE SERVER ROOMS

MICROCLIMATE AND AIR CONDITIONING SYSTEMS MONITORING

Monitoring of the microclimate of server rooms and air conditioning systems

The initial data for monitoring the microclimate of server rooms and air conditioning systems are the following requirements:

-possibility to remote control of the room microclimate parameters

-possibility to remote monitoring of the air conditioning systems equipment conditions

-notification for the occurrence of pre-emergency, emergency conditions at controlled facilities

Operating range of temperature measurement and signal conversion | 40°C…+100°C |

Absolute temperature measurement error in the range from minus 10 to plus 60 ° C | ±1,0 °C |

Operating range of measurement and signal conversion by relative humidity | 0%…100% |

Absolute error of relative humidity measurement in the range from 10 to 90% | ± 2,0 % |

Absolute measurement error of relative humidity in the range from 0 to 10% and in the range from 90 to 100% | ± 3,0 % |

The obtained analog values of temperature and humidity with a period of 1 time in 10 seconds are transmitted to the NOVA SP parameter monitoring device, converted into digital indicators and normalized.

The design of the sensors allows installation both in a wall-mounted version and with a remote sensor. This allows you to measure the temperature and humidity of the air at any point in the room. Temperature sensors are placed on racks with equipment in the “hot” zone, which makes it possible to identify equipment operating with overheating. Combined temperature and humidity sensors are installed on the walls to measure the general parameters of the microclimate of the room. The required number of sensors is selected depending on the number of server racks.

To solve the problem of remote monitoring and control of the equipment of air conditioning systems, two campaigns are used, depending on the installed equipment. The Ethernet/SNMP interface is used to monitor precision air conditioners with network cards. The connection takes place via the SNMP adapters installed on the air conditioners. NOVA SP parameter monitoring devices poll air conditioners with a configurable frequency, and also transmit commands to turn on/off air conditioners and set settings via the SNMP protocol.

For server rooms equipped with Daikin, Mitsubishi Electric, Samsung, Toshiba, LG Electronics air conditioning systems, it is necessary to retrofit adapters with Modbus RTU interface and/or air conditioning co-ordinators. At the same time, the NOVA SP devices are connected both directly to the air conditioners and to the air conditioner co-ordinators. This connection scheme makes it possible to operate air conditioning systems in manual mode with remote control via the Web interface and work in fully automatic mode.

Notification of the occurrence of pre-emergency, emergency conditions at controlled facilities is carried out by sending SMS by regular means of NOVA SP devices to the numbers of employees responsible for the operation of server rooms.

OUR PRODUCTS

THE SERVER ROOMS

POWER SUPPLY MONITORING

Server room power supply monitoring

The initial data for monitoring the power supply of server rooms are the following requirements:

– the ability to remotely monitor the availability of power to server

– the ability to log the operation of the power supply system

– monitoring of UPS and DGS

– notification of the occurrence of pre-emergency, emergency conditions at controlled facilities

For remote control of the availability of power supply, the NOVA SP devices include modules for the input of discrete AC and DC 220 V signals. These inputs are connected to the circuit breakers powering the server racks. Data on the presence of voltage on the automates are periodically read and, in the event of a power failure, personnel are notified. NOVA SP devices have a built-in uninterruptible power supply with a battery life of up to 30 minutes. During this time, NOVA SP manages to transmit information about a power outage to the system server via the main or backup communication channel and send SMS messages. When the power supply appears, the device resumes normal operation.

Logging and archiving of data is carried out by the system server. The user has the opportunity to view the event log with data on the time, place and cause of the emergency event.

Monitoring of uninterruptible power supplies is proposed to be carried out via the Ethernet/SNMP interface. The SNMP/Web adapter network monitoring card installed on the UPS is used. The following parameters are controlled:

– UPS operation status

– availability of input voltage

– Battery status

– approximate estimate of the time to power off when the supply voltage is lost

– emergency messages from UPS

Remote monitoring of the DGS includes monitoring of the following parameters:

– state of operation of the DGS

– the level of diesel fuel in the tank

– AVR position

To monitor the state of operation of the DGS and the position of the AVR, the NOVA SP device is connected to standard outputs of the “dry contact” type of the existing AVR shield. The system provides remote monitoring of these parameters and logging. To remotely monitor the current level of diesel fuel in the tank, it is necessary to install a contactless ultrasonic fuel level senso

OUR PRODUCTS

THE SERVER ROOMS

VIDEO SURVEILLANCE

Video surveillance in server rooms

To solve the problem of video surveillance in server rooms, it is proposed to use cameras and, if necessary, video surveillance servers.

The automated server control system allows, at the time of an alarm or emergency event in the controlled systems, to send an electronic message to the user with a series of photos or videos from the server room at the time of the event.

OUR PRODUCTS

Interested in our services?

Kazakhstan, Almaty, Nursultan Nazarbayev avenue, house 65, office 503